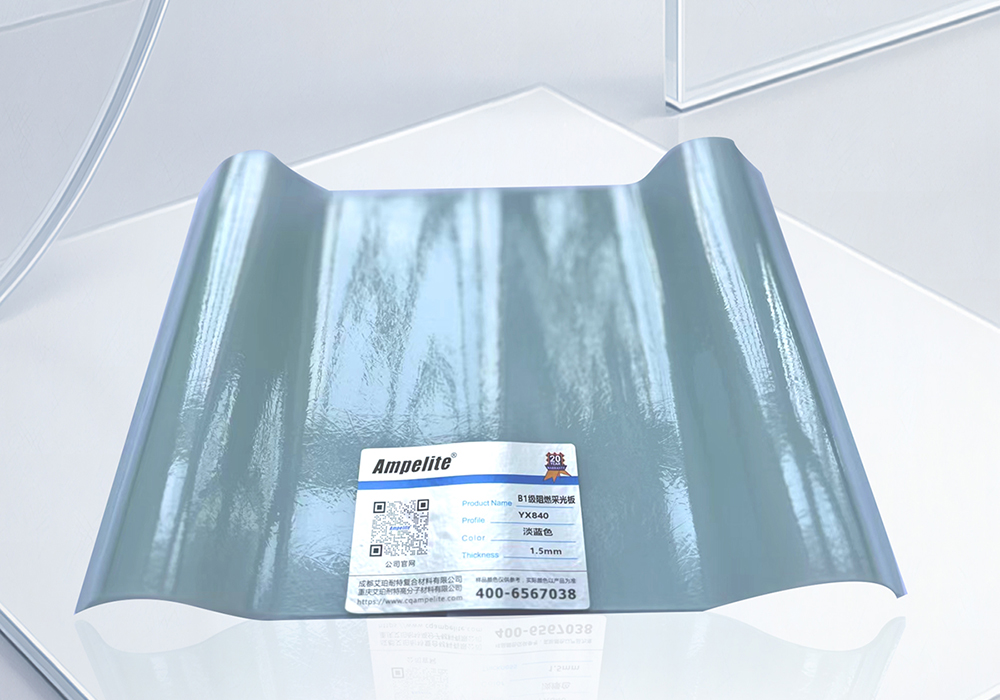

FRP skylight sheet

Main ingredients:

a. Upper film(America DuPont Teijin Films Melinex® 301H Polyester Film)

b. Reinforced polyester

c. Glass fiber(Ashland,America)

1.Product description

Ampelite sheets are described by weight or thickness, with a weight range of 1.52-4.66kg/m² (flat sheet), corresponding to a thickness of 1.0mm-3.0mm with a tolerance of +10%,it’s with a certain shape,are heavier than flat sheets of the same thickness due to different corrugation coefficients. Refractory sheets or anti-corrosion sheets are heavier than ordinary sheets of the same cross-section due to the use of a resin system with a higher specific gravity.

2. Thermal performance

Generally speaking, Ampelite sheet have better thermal stability than general skylight materials and are highly adaptable to strong temperature differences. Within the temperature range of -50℃-120℃, they still have structural integrity, no cracking, and maintain the original prototype (standard sheet are not recommended for long-term use in high temperature environments, as color stability will be relatively poor under high temperature conditions).

3. Strength

Ampelite sheet have a very high strength-to-weight ratio, making them an ideal choice in many application designs. The treatment of the ribs on the surface of the sheet can evenly distribute the various materials inside the sheet, improve the overall strength, and better meet the requirements of outdoor use.

4. Load

Compared with fragile glass and volatile metal materials, Ampelite sheet has particularly good resilience. Because the sheet has extremely strong elastic deformation ability, it will deform when subjected to load or impact, and it will return to its original shape after the external force is removed.

5. Gloss

Ampelite sheet are made of unsaturated polyester resin containing UV absorbers and stable Ashland color paste raw materials to ensure the color stability of the sheet. For sheet with gel coat, the color can be guaranteed to last for a long time.

6. Chemical resistance

Standard Ampelite sheet can meet the general requirements of seaside or occasions with a small amount of corrosive gas. They can be used safely for a long time in dilute halides, salt spray gas, carbon chlorine compounds, weak acid and weak alkali. However, long-term immersion will change the physical properties and appearance of the material. For places with severe or special corrosion, Ampelite can provide a series of specially customized anti-corrosion sheet.

7. Ultraviolet rays

Ampelite sheet can effectively block more than 99% of the ultraviolet rays in the sun, thereby slowing down the fading and degradation of the material and protecting indoor equipment or personnel. The raw materials used in Ampelite sheet fully consider the damage of ultraviolet rays to the sheet and prevent damage to the greatest extent possible. We strive for excellence in the use of curing agents, ultraviolet absorbers, etc., so that the service life of the sheet is extended.

8. Fire resistance

Special requirements or building codes often have fire resistance requirements. For these special requirements, Ampelite provides primary flame retardant and secondary flame retardant types of sheet (flame retardant sheet contain flame retardants or halogens, which have a significant impact on the quality, light transmittance and color of the product, and the yellowing speed of flame retardant sheet is faster than that of ordinary sheet).