|  |

Choosing between FRP (fiberglass reinforced plastic) daylight panel and PC (polycarbonate) daylight panel can be a difficult decision, as they are both commonly used daylight materials in industrial and commercial buildings, but their characteristics and applicable scenarios differ significantly. To help you quickly grasp the key points, we'll first summarize their core comparisons in a table, and then delve into the details and how to choose.

Features/Projects | (Fiberglass Reinforced Plastic) daylight panels | PC board |

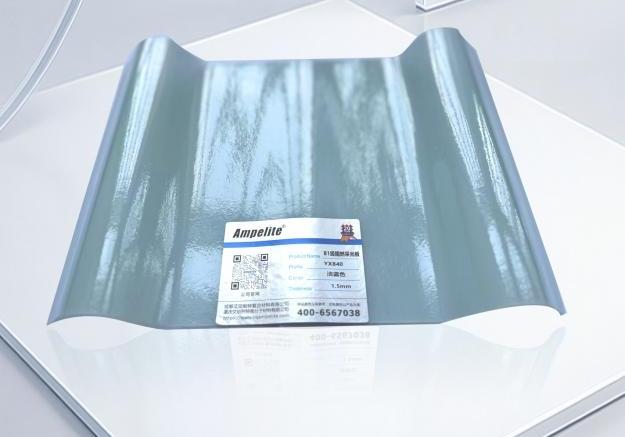

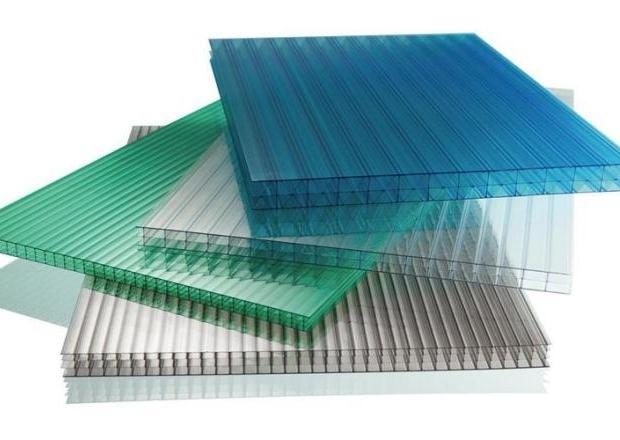

Core components | Glass fiber reinforced plastics (fiber + resin) | Polycarbonate (solid core is polycarbonate sheet, hollow core is polycarbonate sheet) |

Installation complexity | Lower (similar to metal plate mounting) | High (expansion gap needs to be reserved, special adhesive required) Significant risk of water leakage |

Scratch resistance | Better | Poor (surface scratches easily) |

rigidity | It has high rigidity and is not easily bent. | Relying on hollow structures, thin plates are soft |

Chemical corrosion resistance | Excellent , especially resistant to acid and alkali corrosion. | Resistant to weak acids and neutral oils, but not resistant to strong acids and strong alkalis. |

Light transmission performance | Light transmittance is generally between 60% and 90%. Customizable with a wide range of options. | Its light transmittance can reach 89% , comparable to that of glass. |

Temperature range | Available in temperatures ranging from -40℃ to 120℃ Long-term use in the environment | Available in temperatures ranging from -40℃ to 120℃ Long-term use in the environment |

Service life | The service life can be as long as 20 years or more. | due to the protection of the ultraviolet (UV) coating. |

Cost | Low | High |

How to choose based on the scenario ?

When faced with these two materials, you can make a decision based on the specific application scenario .

When FRP (fiberglass reinforced plastic) daylight panels are preferred:

Ø The built environment is subject to significant chemical corrosion, such as factories in the chemical, electroplating, metallurgical, and pharmaceutical industries .

Ø The project budget is relatively limited, and the requirements for lighting are not extremely demanding .

Ø A daylight strip is needed that perfectly matches the existing corrugated steel structure of the factory building .

When PC boards are preferred:

Ø Applications requiring extremely high safety and impact resistance include stadiums, schools, shopping mall daylight, and security booths .

Ø Buildings requiring high thermal insulation performance, such as eco-restaurants, greenhouses, and buildings with heating systems .

Ø It needs to be bent into complex shapes such as arches and curves, for example, corridor canopies and arched skylights .

Installation and maintenance points

Regardless of the materials chosen, proper installation and maintenance are crucial .

FRP (Fiberglass Reinforced Plastic) daylight panels: Ensure a tight fit with the color steel sheet during installation . Although its surface film allows dust to be easily washed away by rain , no special maintenance is required.

PC board: When installing, a gap must be made to allow for thermal expansion and contraction, and the hole diameter must be larger than the screw diameter . At the same time, be sure to protect the UV coating on the surface and avoid using acidic or alkaline glues for sealing .

Hopefully, this detailed comparison will help you make the most suitable choice . If you can share more specific information about your project, such as the building type, the climate of the area and your budget, we can provide more precise advice.