Performance comparison of flame retardant FRP anti-corrosion board, steel plate film anti-corrosion board, and color steel plate sandwich board

1、 Flame retardant FRP anti-corrosion board

Flame retardant FRP anti-corrosion board, also known as fiberglass anti-corrosion board, is a product made of flame-retardant resin, glass fiber, and other materials that are molded in one go using thermoplastic technology. By utilizing the anti-corrosion properties of the product itself, it achieves effective anti-corrosion effects and is widely used in strong corrosive environments such as animal husbandry, non-ferrous metals, smelting, thermal power, chemical engineering, ceramics, etc.

Advantages: This product has super strong corrosion resistance, with an effective corrosion resistance of over 6000 hours in corrosive liquids with a concentration of 15% to 20%, without obvious abnormal performance. It also has effective tensile strength and bending strength, suitable for use in corrosive or severely corrosive environments. The minimum service life of the quality guarantee is 20 years.

Disadvantage: In terms of flame retardancy, this product can only achieve a maximum of B1 level flame retardancy (oxygen index ≥ 30).

Figure 1 Application of flame retardant FRP anti-corrosion board in the external enclosure of animal husbandry buildings

Figure 2 Application of flame retardant FRP anti-corrosion board in indoor suspended ceilings of animal husbandry buildings

Figure 3: Overall application of flame-retardant FRP anti-corrosion board in livestock construction 1

Figure 4: Overall application of flame-retardant FRP anti-corrosion board in livestock construction 2

2、 Steel plate film anti-corrosion board

Steel plate film anti-corrosion board is made of steel plate as the substrate, on which PET film layer is applied on the upper and lower layers, and the anti-corrosion effect is achieved through the film layer applied on the upper and lower layers.

advantage:

1. This product can achieve A2 level flame retardancy;

2. Theoretically, the weather resistance of the material is slightly higher than that of ordinary color steel plates in natural environments.

Disadvantages:

1. This product cannot be used in corrosive environments, especially in strong corrosive environments such as heavy industry and animal husbandry. Due to the presence of many corrosive substances or animal feces during production and operation, a large amount of ammonia gas will be produced, which will cause serious corrosion to materials such as steel plates.

2. At present, the film sticking technology is still in its immature stage. The thermal expansion rates of metal and resin films are different, and the product will bulge and break. In a corrosive environment, corrosion will begin from the point of rupture; According to previous cases, in severe cases, corrosion occurs within two to three years, while in normal corrosion cases, replacement must begin after about seven to eight years.

3. Due to product characteristics limitations, most of the products can only be molded in the factory. During transportation and installation, the film cannot be completely damaged, which is also a major risk of corrosion.

4. The end of the product cut on site is not covered by a film and can also corrode.

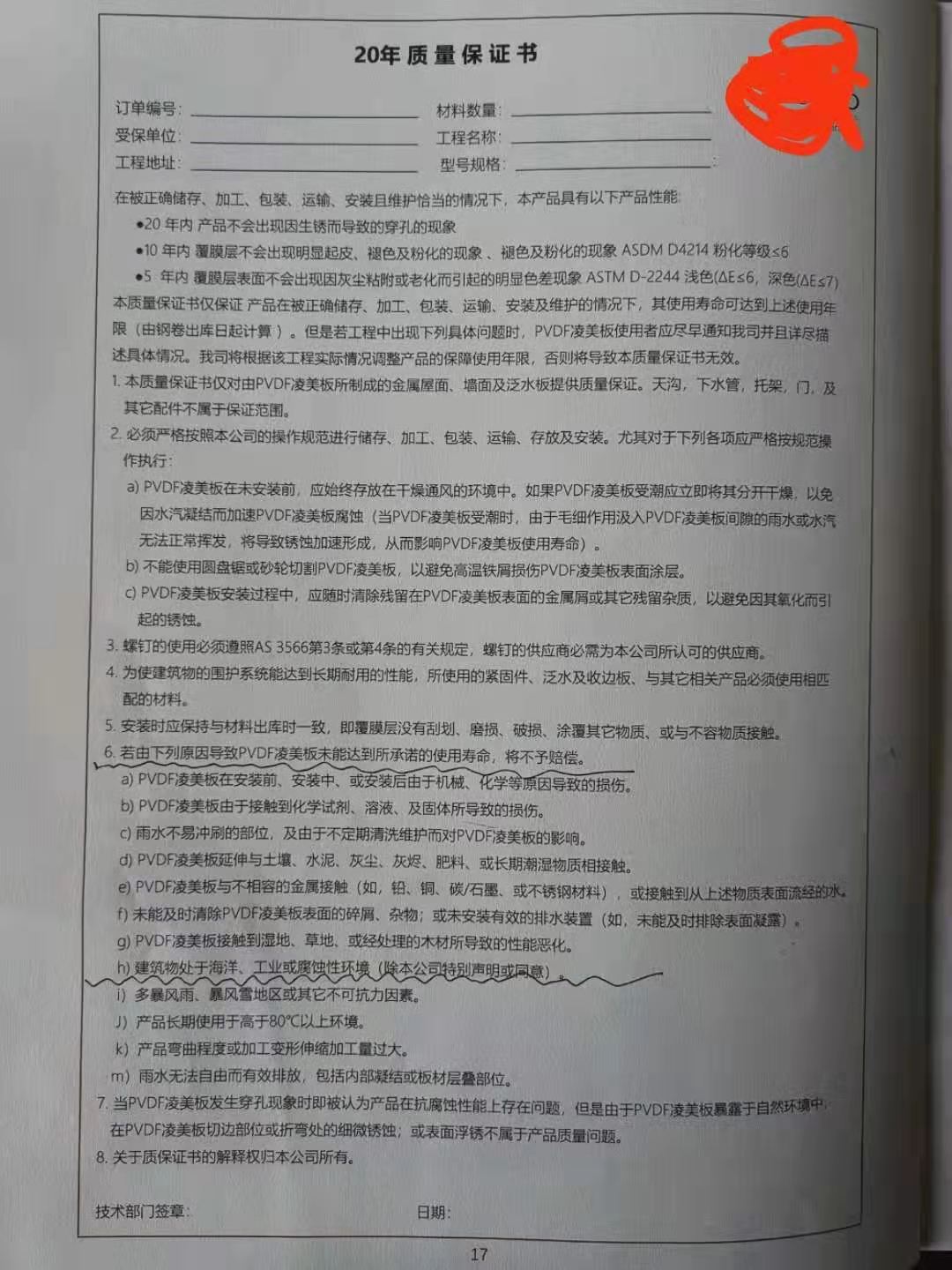

Figure 5: Quality Assurance Certificate for PVDF Anti corrosion Board of a Certain Brand

In the quality assurance certificate of a certain brand of PVDF anti-corrosion board, it is explicitly stated in Article 6 (d) and (h) that it cannot be used in corrosive environments. And other terms fully demonstrate that the product cannot effectively achieve anti-corrosion effect when facing strong corrosion situations.

3、 Color steel plate sandwich panel

Color steel plate sandwich panel, made of two layers of metal panels and a middle layer of polymer insulation core, is a commonly used building material.

Advantages: High strength, easy installation.

Disadvantages: The overall corrosion resistance is weak. The corrosion resistance of different color steel sandwich panels is determined by the quality of the upper and lower metal color steel plates. The insulation effect is determined by the material of the middle core. Ordinary low-end color steel sandwich panels with benzene core have slightly lower prices and weak corrosion resistance, and are generally used in temporary constructions such as ordinary movable panel houses. High end color steel sandwich panels with polyurethane cores are expensive and have better corrosion resistance than ordinary color steel sandwich panels. They are mostly used in buildings without corrosion sources.

Figure 6: The use of ordinary color steel plate sandwich panels in a certain breeding plant, with a service life of 5 years

In summary, FRP anti-corrosion board has significant advantages in terms of usage effectiveness, warranty period, and construction cost. In fact, it has gradually become the preferred material for maintenance systems of enterprises with corrosion sources in production and operation, such as ceramics, non-ferrous metals, thermoelectric, and large livestock breeding enterprises.